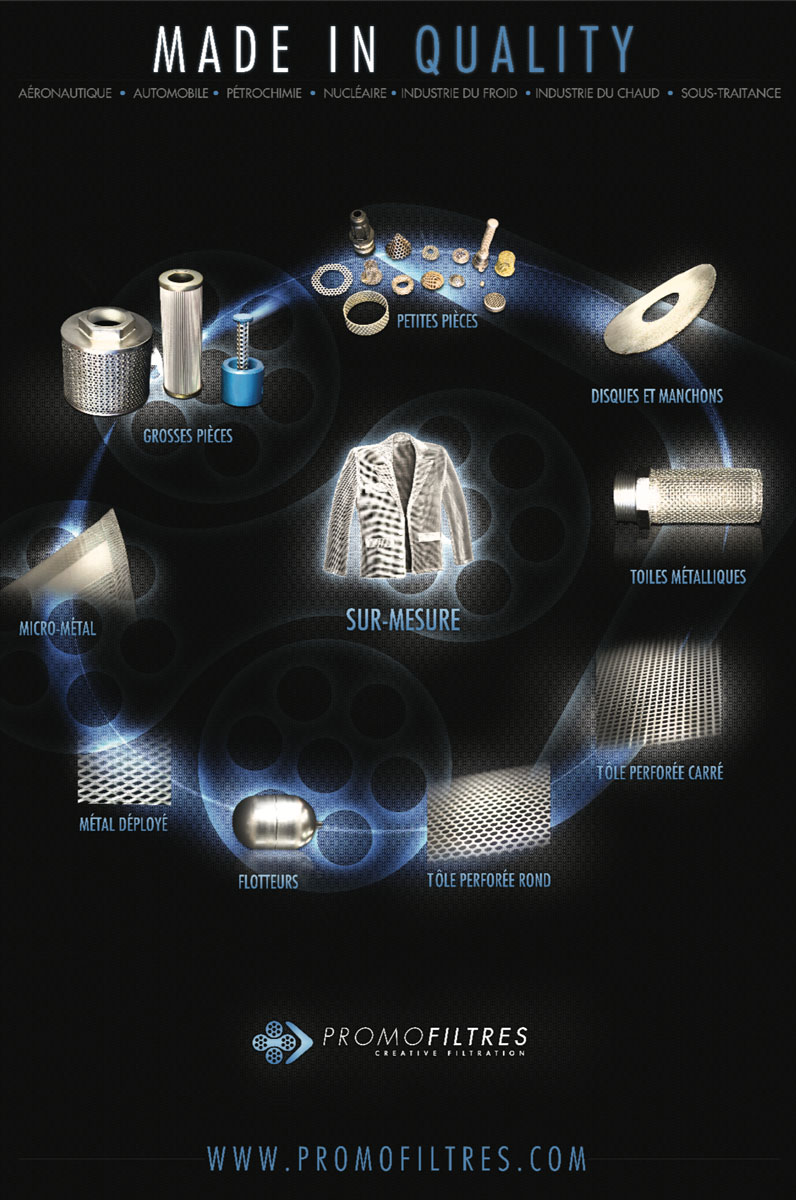

Our products

Cartridge, baskets, strainers

Filter sieve

Floater

Filter media

Filter frames

Special filters

Filtration cartridges - An industrial filtration specialist

Manufacturing filtration cartridges

The filter media is the central part of an industrial filtration cartridge. The filter media is needed to separate the pollutant from the fluid. When the fluid passes through an industrial filtration cartridge, the media fibres will only let the fluid pass while retaining the pollutants.

We specialise in manufacturing industrial filters and can make your custom made industrial cartridges.

Depending on your needs, we can produce your custom made industrial filter cassettes.

Made in France

International shipping

From single parts

to series production

to series production

Some examples of our products:

- Filtering cartridge with folded paper media, perforated metal inner frame, pressed or embossed collar and base.

The folded filter element reduces filter surface compared with a smooth filtration element. - Cartridge with pressed cup, folded metal mesh and inner and outer frames made of perforated metal.

- Cartridge with a six-sided threaded fitting, filtering element made from folded metal mesh, perforated metal outer body.

The folded filter element reduces filter surface compared with a smooth filtration element. - Cartridge with folded paper media and an outside frame made of expanded metal, a perforated inner metal body, pressed cups or ones pushed out at both ends with and without sealing gaskets.

The folded filter element reduces filter surface compared with a smooth filtration element. - Cartridge with folded paper media and an outside frame made of expanded metal, a perforated inner metal body, pressed cups or ones pushed out at both ends with and without sealing gaskets.

The folded filter element reduces filter surface compared with a smooth filtration element. - Filtering cartridge with woven metal filtering element.

Woven part retained by an inner frame and an outer frame made from square hole perforated panels that are largely transparent.

Solid base, filter retained by drilled collar provided with a handle. - Set of cartridges with a filtering mesh of up to 9µ, micro plasma weld line to guarantee sealing.

Plasma welding also seals the edges of the mesh to the end pieces.

Perforated metal inner frame, drainage mesh between the filtering mesh and the perforated metal.

Mechanical parts made by turning or undercutting. - Cartridge with a folded cloth filter media crimped onto the end rings, with a perforated metal inner frame.

The advantage of crimping is that sealing is ensured with no need for glue.

A continuous weld that sandwiches the folded media between the ring and a ferule also eliminates the need for glue and is easier to apply for small quantities. - Compressed metal weave filter.

- Metal weave filter rolled around itself.

- Folded metal mesh.

The filtering mesh may or may not come with one or two reinforcing meshes to protect or bring it greater rigidity. - Folded paper media, paper reinforced with a metal mesh.

Manufacture of industrial filters

Do you have a project or a need ?

Find out why you can trust us

Expertise built on excellence

for your satisfaction

Manufacturing

from drawings or

model parts

from drawings or

model parts

Serving professional

and individual customers

and individual customers

From single parts

to series production

to series production

From 10µm

to several mm

to several mm

Made in France

International shipping

They trust usDiscover our references

3 Rue des Charpentiers

95330 Domont

95330 Domont